FTC Robotics

First Tech Challenge is a yearly robotics competition for high school students. Our team, Stuy Fission 310, has been around since the competition began in 2007. We built our best robot yet for the 2022-2023 season, machining and 3D printing all of our own parts. Not to mention, the entire codebase was refactored to employ modern techniques and paradigms that made development a breeze.

Power Play Season

This was the 2022-2023 FTC Robotics season, and it featured our best robot yet, designed with simplicity and reliability in mind. It featured a maximum-scoring autonomous program with real-time error-correcting pathfinding, and manual controls with a healthy dose of automation, making it our easiest robot ever to operate.

At the end of the season, we were ranked 34 worldwide. I was incredibly proud of my team and the progress we made in such a short period.

Technical Details

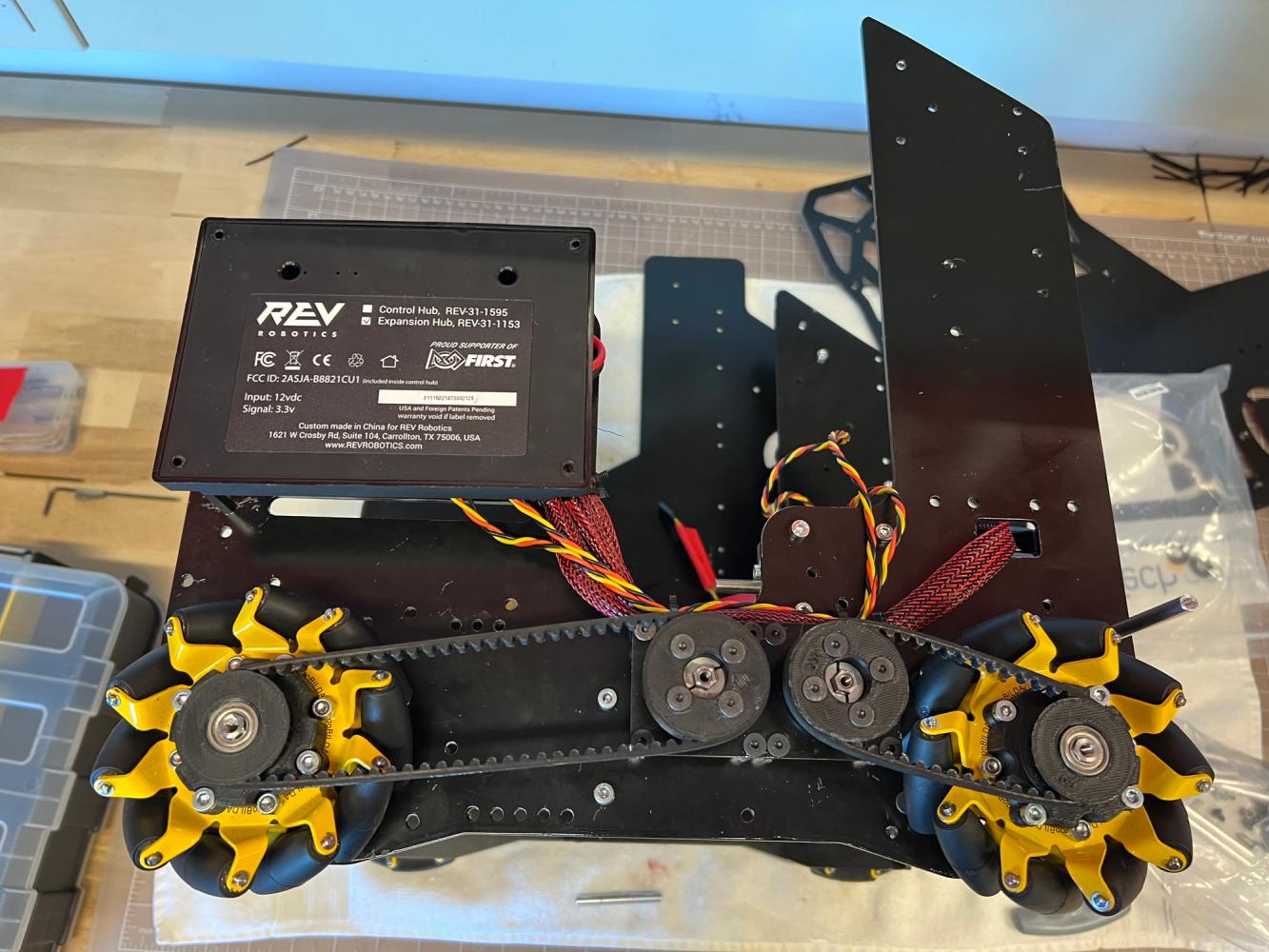

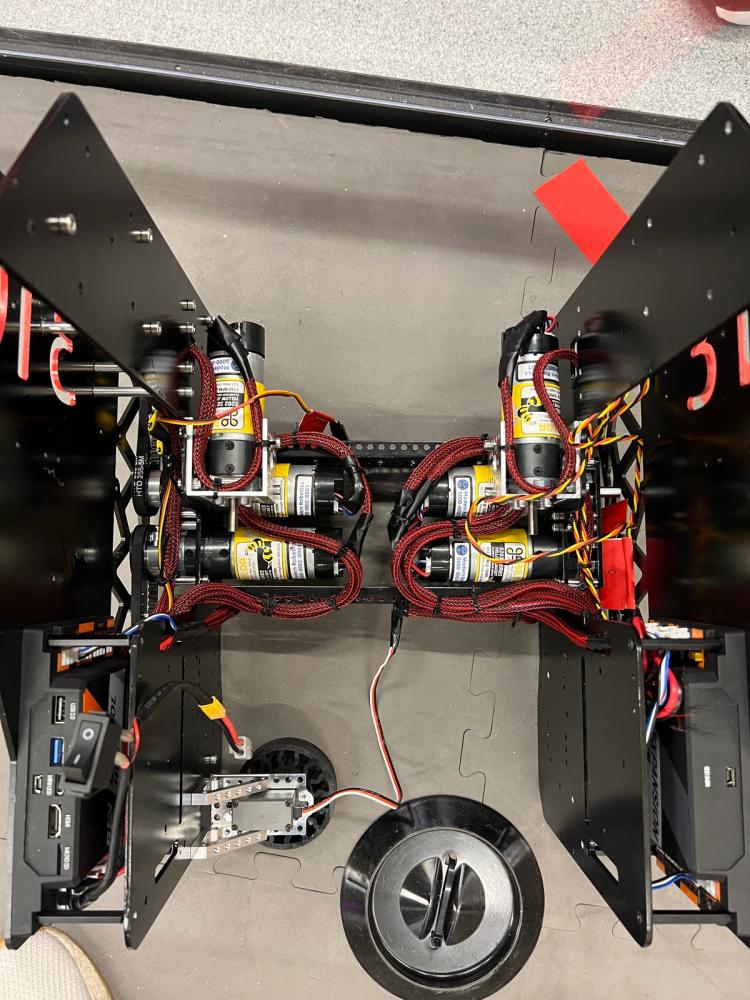

Everything you see on the robot was custom-made in-house. This is uncommon in high school robotics, but from the aluminum CNC'd side panels to various laser-cut alignment guides and 3D printed arms, it was all designed by our team, and manufactured by us.

FTC robotics is competition robotics, so a lot of time was spent optimizing our design for speed and efficiency. We used high-powered motors and geared them to create a drivetrain capable of driving at 60 in/s (3.5 mph). The robot has to place cones on top of poles up to 4 feet high but must be able to fit within strict 18-inch size guidelines, so we designed an extendable slide system to reach those heights. It was impressive from a hardware standpoint, but on the software side, it inspired the creation of FissionLib, our Java code library which implements several smart DC motor control functions.

Among many other useful features, our MotionProfiledDcMotor class enables smooth S-curve velocity curves which is vital for controlling our linear slide extensions while minimizing jittery motion and stressors.

Sleek Design

Of course, nobody cares that your robot works if it doesn't look good doing it.

Our team colors are black and red, so we decided to go with a matte black, sleek design, for the robot.

Pained aluminum arm cross-brace.

Sidepod showcasing pulley drive system and cable management.

Fully assembled robot.

Top view of the robot, showcasing drive motors, and cable management.